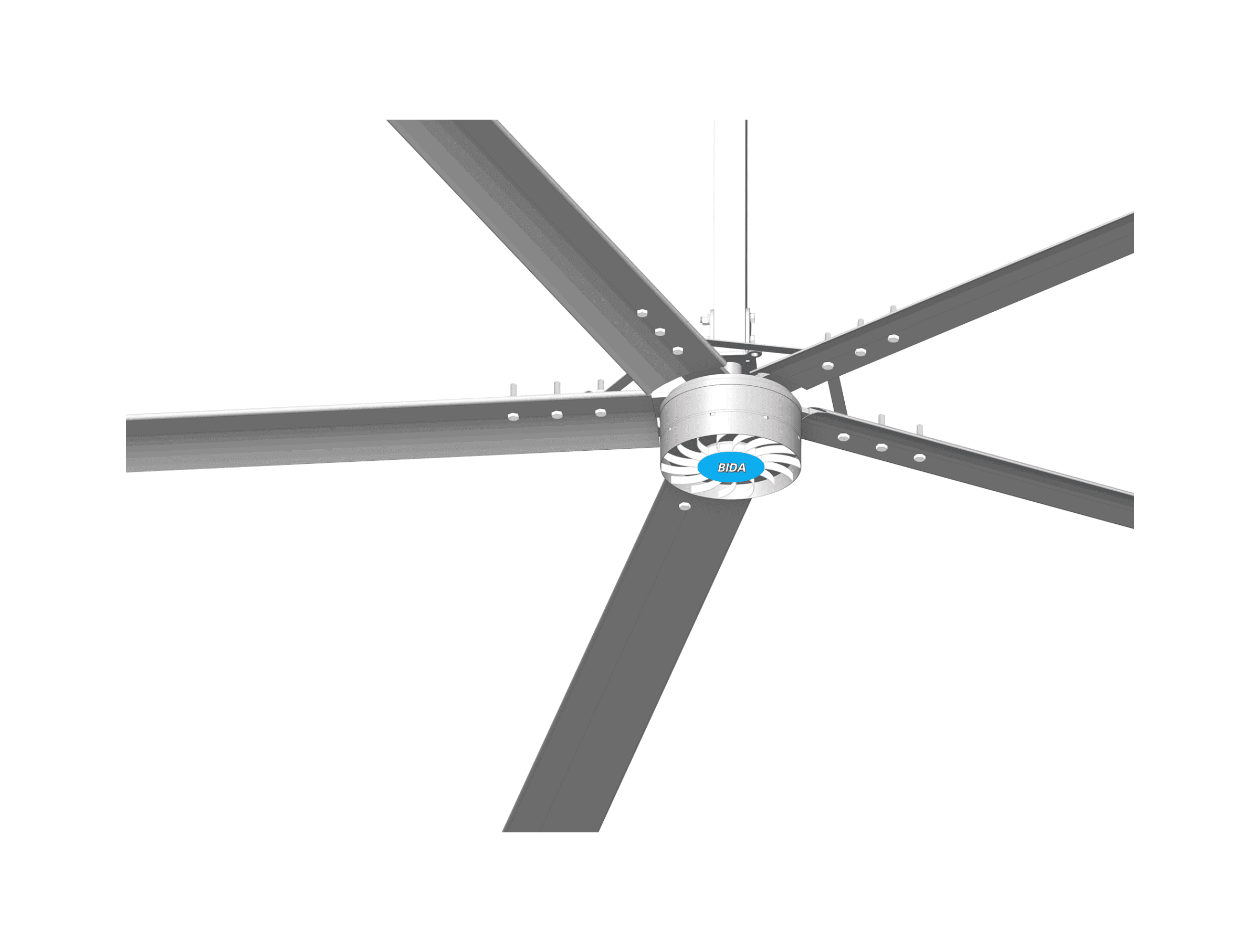

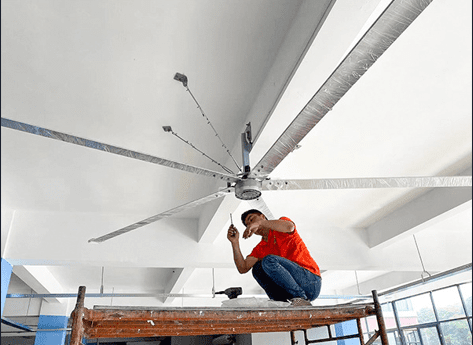

18ft Direct Drive Big HVLS Fan for Philippines and other South East Asian countries

Gearless direct drive HVLS Industrial Ceiling Fans specially dedicated for large scale space. The streamlined fan blade adopts aerodynamics principles and advanced process, our DOB series with the diameter from 5.2m-7.3 m to meet your facility area and create plenty of comfortable natural wind.

Additional information

| Model | |

|---|---|

| Blade Diameter | 20ft (6.2m) |

| Max.Speed | 60rpm |

| Motor Power | 1.3kw |

| Number of Blades | 5 |

| Fan Weight | 110kg |

| Noise | 39db |

| Power Supply Form | 380v or 220v |

Main Introduction

Product Details:

BIDA DOB Series HVLS Industrial Ceiling Fan adopt Permanent Magnet Direct Drive Motor with outer rotor design, it is very energy saving and working quite with low noise. HVLS PMSM integrated machine adopts the international leading field-oriented vector control technology, synchronous motor control technology, and static motor parameter self-learning algorithm, which can match various types of PMSM motors. The matching accuracy is high, the output power factor is high, the energy-saving effect is good, the motor running current is small, and the current fluctuation is small, so the motor temperature rise is small.

Permanent magnet direct drive fan advantages:

1)More energy saving effect.

2)Operating noise is significantly reduced.

3) Service life and reliability are significantly improved.

4)reduction gear box is eliminated ,pollution due to lubricant leakage does not occured.

5)Maintenance-free for the entire life.

6)A standard factory building of 10,000 square meters only needs to install 5-10 large-scale 7.3 meter fans, which is more than 70% energy-efficient than traditional distributed small fans.

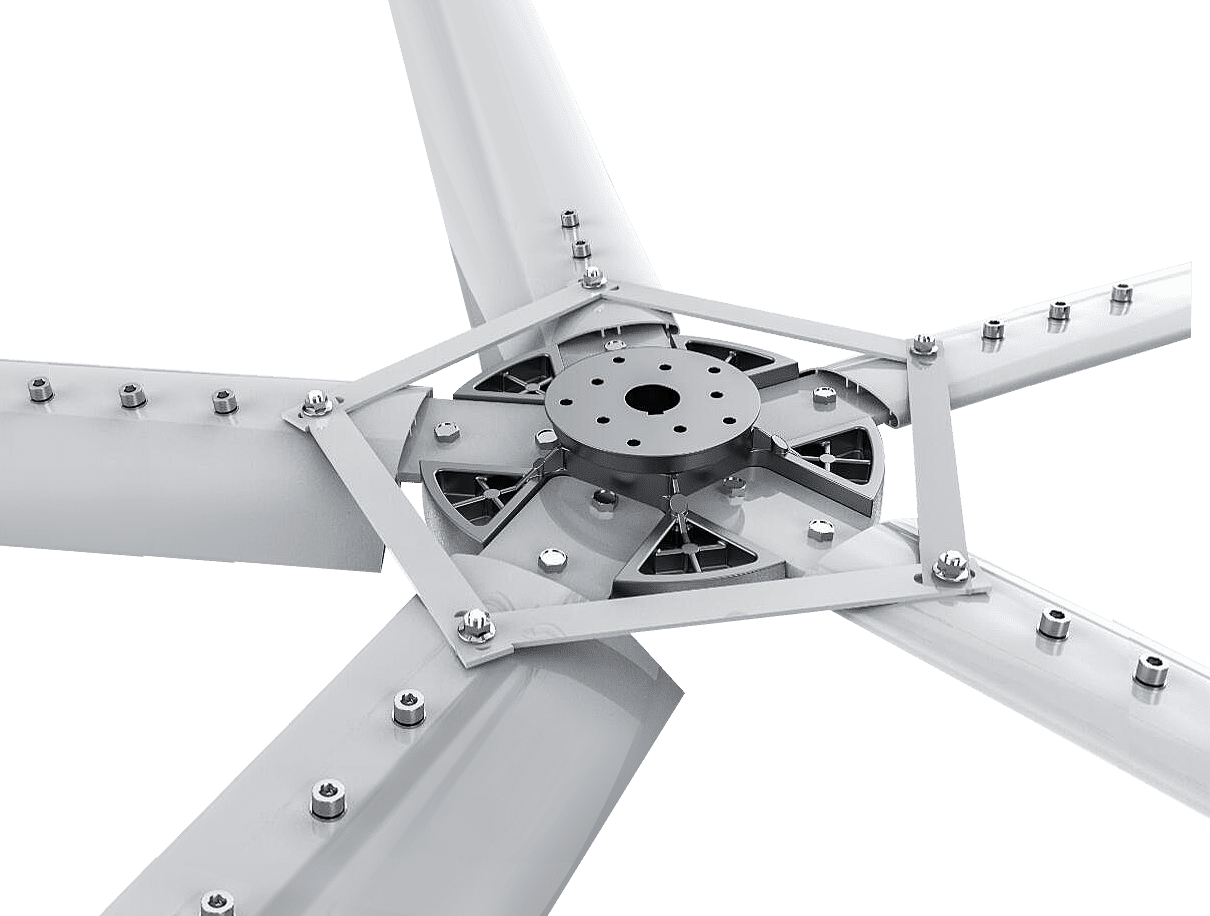

Main Components

PMSM motor (External Rotor)

It is used more for medium size HVLS fan is a very cost-effective optional choice.

Compared with the traditional brush motor, induction motor, it has a better dynamic performance, higher efficiency, longer life, lower noise, free maintenance, etc.

Our PMSM motor adopt unique rare earth NdFeB magnets, rotor and stator, and with its unique design, the overall dynamic performance improved significantly, 300N.M the highest torque in the world, higher efficiency and better stability.

Control System

Top level electrical configuration in HVLS industry, famous brand electrical components, with building safety protection module which will shut down the output automatically in case of some accidents.

Servo drive system can make fan have a fast reaction with DSP control core and inner complex control algorithm. In addition, it has continuously variable, precise localization and the protection system with over voltage,over currents.

Japan NSK Bearings

Using Japanese NSK high temperature bearing bearing, high precision, strong heat resistance, can be used for a long time without maintenance. The advantage is that the starting friction is small, and the difference between the sliding friction is also small, and it can be used even in a negative clearance (preload state).

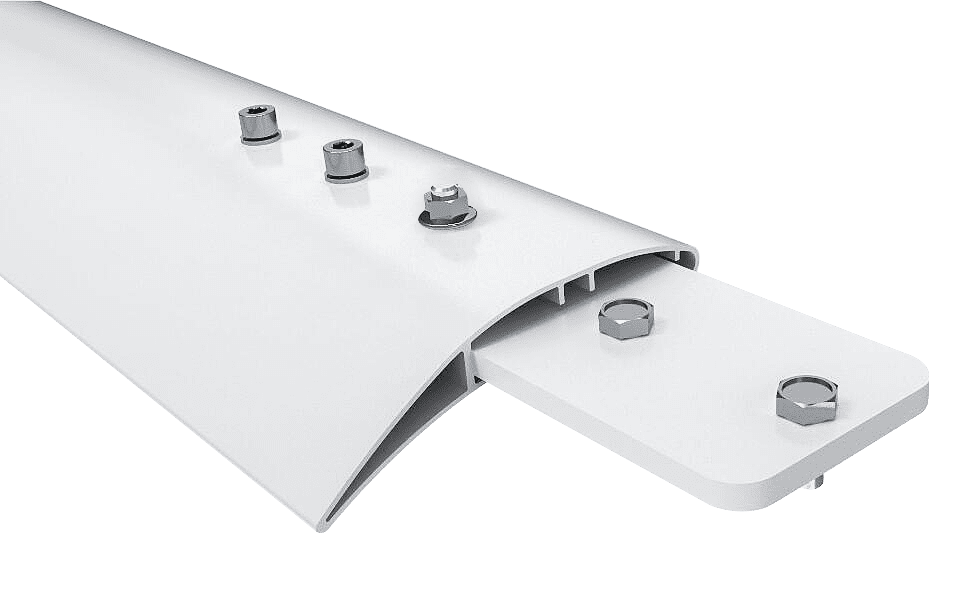

Airfoil Blades

Adopt imported special high strength aircraft grade magnesium, VFD processed in surface, and aerodynamics fan blade design.

Made of high quality aviation aluminum magnesium alloy, anodized with T6 heat treatment, strengthening support system inside which increases the strength of fan blade and avoids the drop of fan blade tail and the loss and fatigue of fan blade to connecting pieces completely.

Parameters

Installation Condition

1. Suitable for any building with a ceiling height of 3.5 meters or more.

2. The load bearing capacity of the roof structure should be more than 150kg, the max. total running weight of the fan equipment is about 125kg.

3. Make sure that the fan is installed without chandeliers or other obstructions.

4. It’s not recommend for installation at the site with heat sources or lampblack occasion.

Related products

-

18ft (5.5m) China Latest HVLS Permanent Magnet Synchronous Motor Hvls Factory Large Ceiling Fan

Read more -

24ft/7.2m PMSM Motor Industrial HVLS Ceiling Fan Made In China

Read more -

24ft PMSM motor HVLS ceiling fan for animal husbandry

Read more -

PMSM Motor Industrial HVLS ceiling fan for warehouse/factory/workshop

Read more